We know that our products protect plants and maintain a safe food supply, but how do we know if they are safe for farmers and bystanders while being applied? We know because we test our products thoroughly so that we can be absolutely certain that they are as safe for humans as they can possibly be. And we keep improving our systems so that our measurements of hazard risks are the most accurate available.

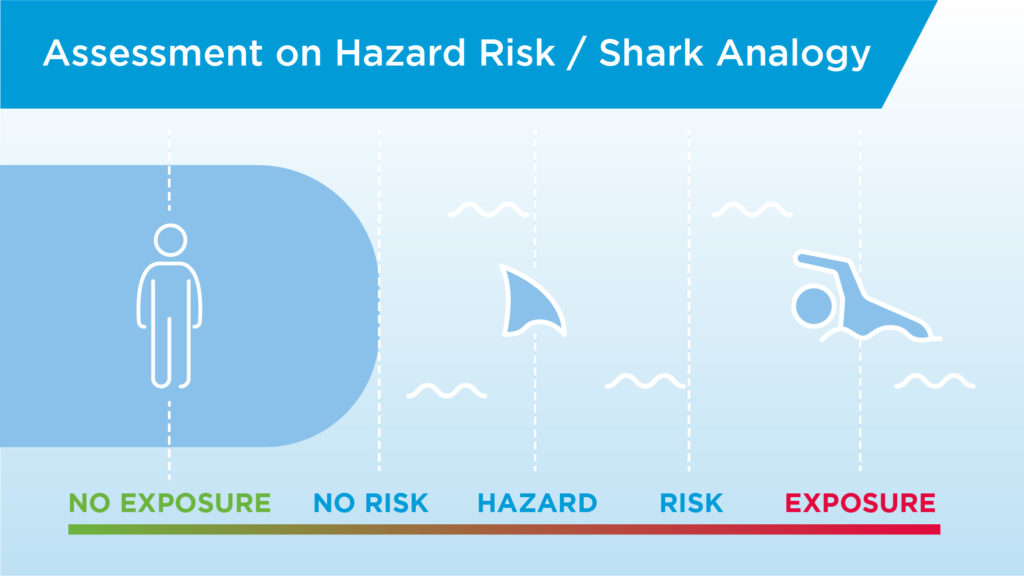

Our assessment of hazard risk is best explained through an analogy to sharks. Sharks can attack humans, but the risk of a shark attack is only serious if you go swimming in areas where sharks roam. However, you face little risk of getting bitten when you stand in shallow water, far from the shark-infested seas. This is a basic example of hazard and risk assessments. The principle is simple: hazards are unlikely to be a risk if you are not exposed to them.

This risk concept also applies to regulations for Plant Protection Products (PPPs). Models were first built in the 1990s to estimate the exposure of users during the entire pesticide application process. The risk is assessed after the estimated exposure was compared to the hazard of the product.

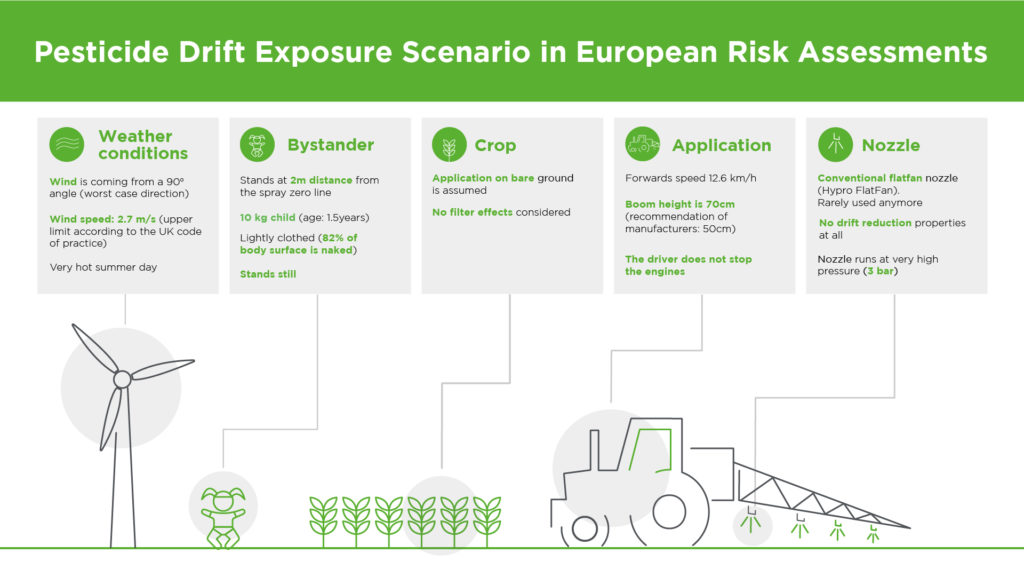

A decade later, new risk assessments were made for people who are not directly involved in pesticide application: bystanders and residents. These might be people who are inside or directly adjacent to the area where the pesticide application is in process or has recently taken place. These individuals may be exposed, for example, through direct drift on a windy day, when the wind blows spray or residue towards them. This theoretical worst-case scenario is explained below:

Although this ‘perfect storm’ worst-case scenario is highly unlikely, it was addressed in regulations in the early 2000s.[1] With no hard exposure data at hand, drift fallout data (residues that land on the ground outside the treated field) was used to estimate bystander exposure.

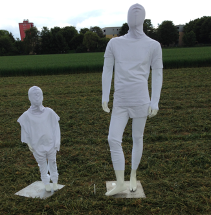

However, by the early 2010s, there was a scientific breakthrough on bystander exposure estimations. An exposure model called BREAM (Bystander and Resident Exposure Assessment Model), developed by independent researchers in the UK, looked at bystander exposure using real measured data.[2] The model measured the residue that fell on two types of life-sized mannequins, representing child and adult, placed next to a field:

The BREAM exposure model was a milestone in estimating bystander safety, and after 2016, European regulators began using it.[3],[4]

Bystander modelling continued to develop, and in 2018, a wind tunnel experiment was designed to measure the collection efficiency of objects in a drifting spray plume. The new model took account of wind speeds, droplet sizes, and object sizes caught in the spray drift. This approach resulted in a revised model, BREAM2,[5] that further improves exposure predictions. Thanks to BREAM2, we have a much more accurate understanding of the relationship between airborne spray and exposure when we factor in variables like wind turbulence and boom height fluctuations. This improved statistical analysis and additional data means that BREAM2 exposure modelling is much more realistic than the original BREAM model.

Even more recently, drift reducing technologies were taken into account. BREAM3[6] goes even further than BREAM2. The latest model shows that drift nozzles can reduce potential bystander exposure in a directly proportional way: when off-target drift falls by 90%, the bystander exposure also drops by 90%. In the BREAM3 model, researchers conducted two wind tunnel experiments using nozzles and pressures with a range of nominal drift reduction, as well as three different spray liquid types. They found very strong evidence that a nozzle/pressure combination can reduce bystander exposure up to 90%.

If we go back to the example of swimming with sharks, the use of drift reducing technologies is akin to using a shark cage. Just as a shark cage protects a diver, a drift reducing nozzle reduces pesticide exposure to a bystander.

We now have stronger data and better exposure estimations. But neither BREAM2 nor BREAM3 is currently considered by regulators in risk assessments, despite the fact that both new models prove their exposure prediction quality is much better than that of the original BREAM. Even more accurate data will emerge in the years to come, enabling us to develop newer and better bystander exposure models. Ultimately, this will make it much easier for decision-makers to answer the question: Is this product safe?

Our industry is calling on regulators to accept the BREAM2 model in place of the original BREAM. As technology improves, so too should EFSA’s guidance on non-dietary exposure.

- [1] Martin S. et al. (2008) [Guidance for Exposure and Risk Evaluation for Bystanders and Residents Exposed to Plant Protection Products During and After Application; J. Verbr. Lebensm. 3 (2008): 272-281 Birkhäuser Verlag Basel] and Bundesanzeiger (BAnz), 06 January 2012, Issue No. 4, pp. 75-76.

- [2] Kennedy et al. BREAM: A probabilistic bystander and resident exposure assessment model of spray drift from an agricultural boom sprayer. Comput Electron Agric 2012;88:63–71.

- [3] EFSA (European Food Safety Authority), 2014. Guidance on the assessment of exposure of operators, workers, residents and bystanders in risk assessment for plant protection products. EFSA Journal 2014;12(10):3874, 55 pp., doi:10.2903/j.efsa.2014.3874.

- [4] Commission Guidance Document. Guidance on the assessment of exposure of operators, workers, residents and bystanders in risk assessment for plant protection products. SANTE-10832-2015 rev. 1.7, 24 January 2017.

- [5] Butler-Ellis, M. C., 2018. Improvements in Modelling Bystander and Resident Exposure to Pesticide Spray Drift: Investigations into New Approaches for Characterizing the ‘Collection Efficiency’ of the Human Body. Annals of Work Exposures and Health, 2018, 1–11. doi: 10.1093/annweh/wxy017 https://www.fera.co.uk/the-bream2-calculator

- [6] Butler-Ellis, M. C., 2021. Wind tunnel investigation of the ability of drift-reducing nozzles to provide mitigation measures for bystander exposure to pesticides. Biosystems Engineering 202 (2021), 152-164. https://doi.org/10.1016/j.biosystemseng.2020.12.008